Product Introduction Product Advantages Working Principle Technical Parameter

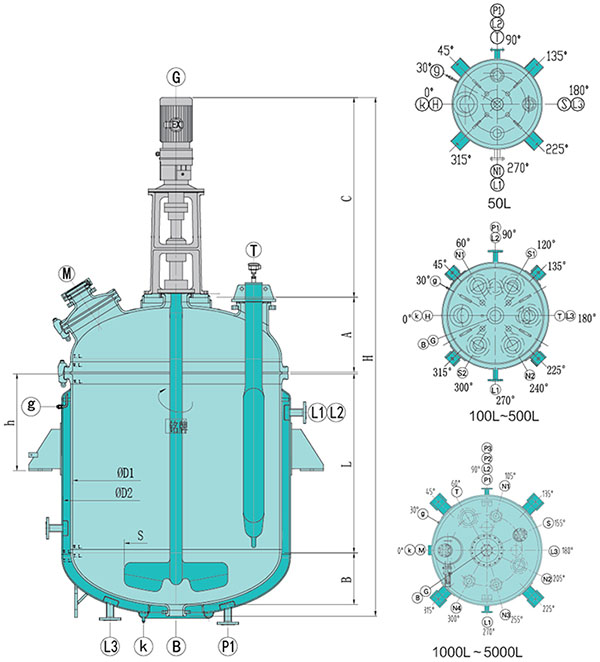

| Model (Open Type) | AE50 | AE100 | AE200 | AE300 | AE500 | AE1000 | AE2000 | AE3000 | AE4000 | AE5000 |

| Nominal Capacity (L) | 50 | 100 | 200 | 300 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 |

| Full Capacity (L) | 70 | 127 | 247 | 369 | 588 | 1245 | 2179 | 3380 | 4348 | 5435 |

| Heat Exchange Area (m2) | 0.54 | 0.84 | 1.5 | 1.9 | 2.64 | 4.5 | 7.2 | 9.3 | 11.7 | 13.4 |

| Shell I.D. (mm) | 500 | 600 | 700 | 800 | 900 | 1200 | 1300 | 1600 | 1600 | 1750 |

| Jacket I.D.(mm) | 600 | 700 | 800 | 900 | 1000 | 1300 | 1450 | 1750 | 1750 | 1900 |

| Reference Weight (kgs) | 380 | 450 | 710 | 950 | 1180 | 1900 | 2700 | 3700 | 4200 | 5300 |

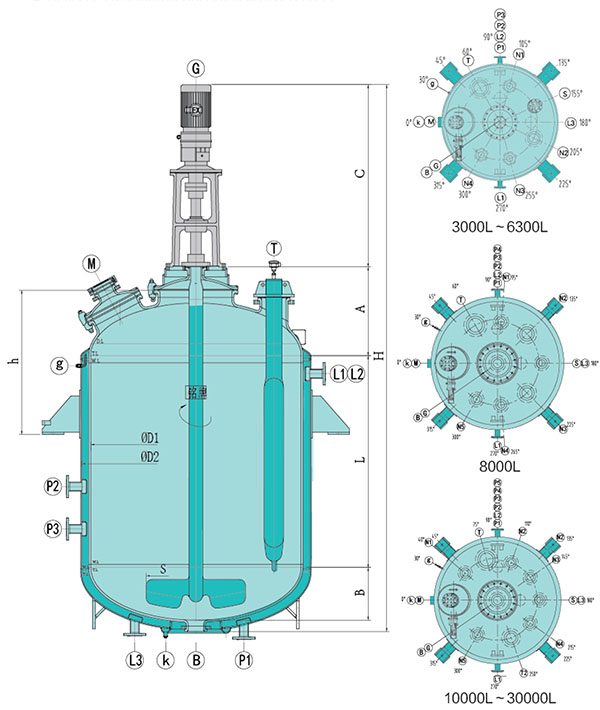

| Model (Close Type) | CE3000 | CE4000 | CE5000 | CE6300 | CE8000 | CE10000 | CE12500 | CE16000 | CE20000 | CE30000 |

| Nominal Capacity (L) | 3000 | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | 20000 | 30000 |

| Full Capacity (L) | 3811 | 4780 | 6011 | 6866 | 9060 | 11674 | 13651 | 17446 | 21790 | 33500 |

| Heat Exchange Area (m2) | 9.74 | 12.16 | 14.89 | 19.89 | 18.36 | 21.35 | 24.89 | 29.48 | 34.04 | 45.36 |

| Shell I.D. (mm) | 1600 | 1600 | 1750 | 1750 | 2000 | 2000 | 2000 | 2200 | 2200 | 2600 |

| Jacket I.D.(mm) | 1750 | 1750 | 1900 | 1900 | 2200 | 2200 | 2200 | 2400 | 2400 | 2800 |

| Reference Weight (kgs) | 3600 | 4030 | 5200 | 5550 | 7600 | 8900 | 10300 | 14300 | 14700 | 22200 |