Product Introduction

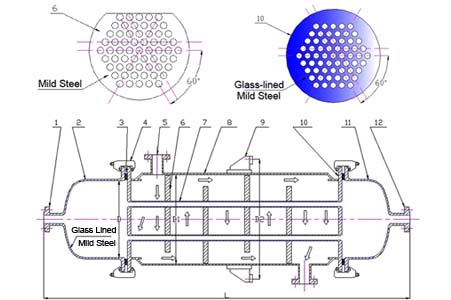

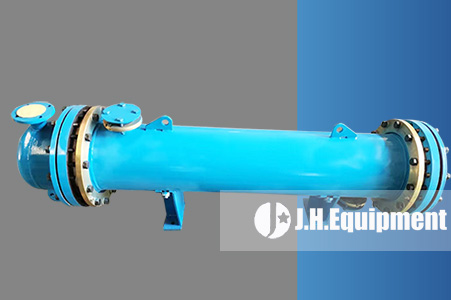

The J.H. glass lined shell and tube heat exchanger has two models, one model consists of a glass lined shell, a bundle of exterior glass-lined tubes fixed on tube plates each side. The heating or cooling fluid runs through the tube side while the corrosive fluid flows over the shell side.

The other model consists of a carbon or stainless steel shell, a bundle of interior glass-lined tubes fixed on tube plates each side. The corrosive fluid will go through the tube side while the heating or cooling fluid flows over the shell side.

All contact parts with corrosive liquid of both models including tube plates are glass-lined or PTFE covered. The J.H. glass lined shell and tube heat exchanger has high heat-exchange efficiency, good corrosive-proof property and able to work under pressure max. 0.6MPa both shell and tube side.

【Production Capacity】: 5~60m2

【Optional Structure】: Vertical, Horizontal

【Application Industries】: Applicable for most acidic corrosive environment that existed in chemical, pharmaceutical, biological, pesticide, dyestuff industries etc.

【Application Mediums】: Various organic and inorganic acids such as sulfuric acid, nitric acid, but not recommended to be used for hydrofluoric acid and hot phosphoric acid with high concentration.