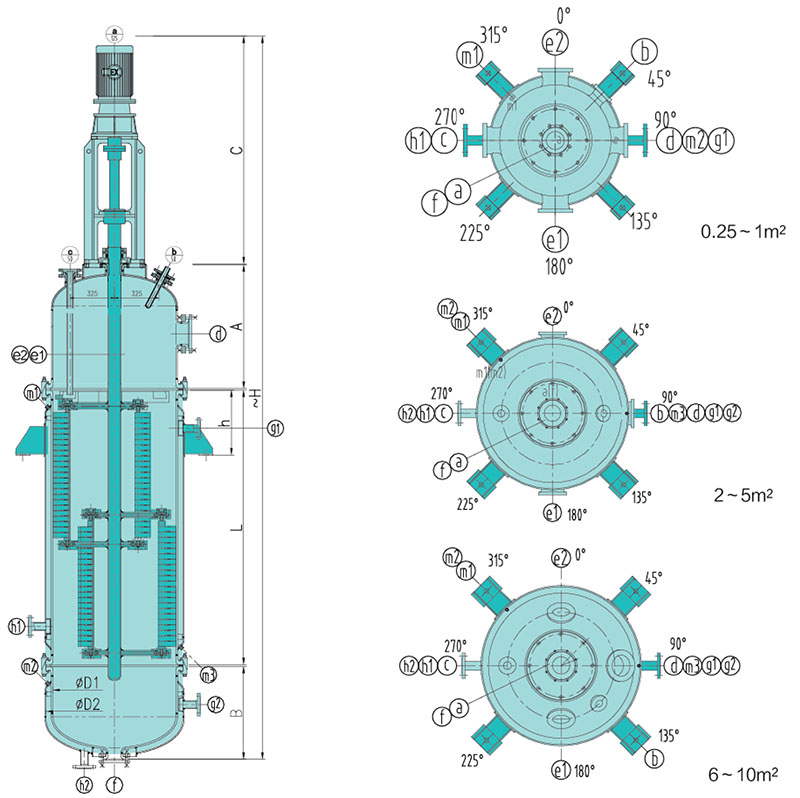

Product Introduction

The J.H. glass lined wiped film evaporator is designed to continuously separate volatile compounds by introducing mechanically agitated, thin film of feed material to a heated surface. The shore residence time allows for efficient and reliable processing of a wide variety of high-boiling, heat sensitive and/or viscous products.

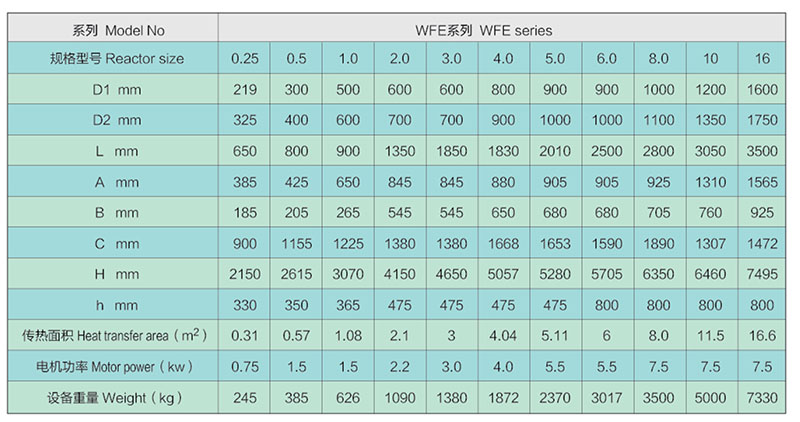

【Production Capacity】: 0.5-8m2

【Application Industries】: Chemical, polymers & resins, pharmaceuticals, food etc.

【Application Mediums】: Hard-to handle, heat sensitive and viscous materials, which maybe strong acidic corrosive.