Product Advantages

*Superior glass-lining against various corrosive chemicals.

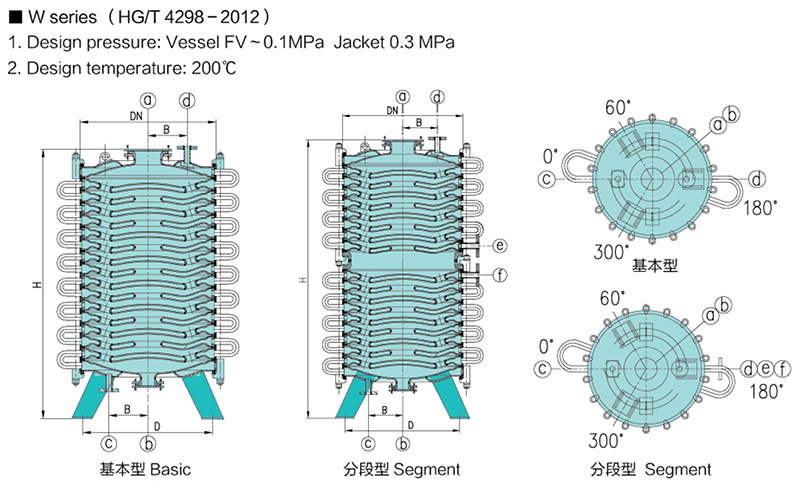

*High condesing efficiency, compact design, small size which saves space of installation.

*Plates can be easily replaced, it is much easier for maintenance compared with glass lined shell & tube condenser.

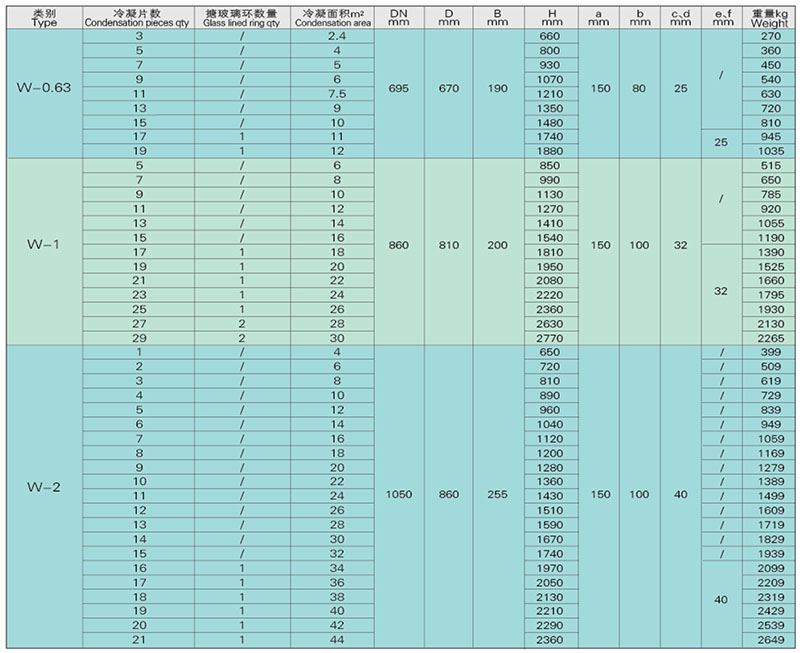

*According to the requirment of the specific process, numbers of glass-lined plates can be increased or decreased, thus total heat exchange of the condenser can be adjusted. This is very flexible and useful for certain circumstances.