Product Introduction

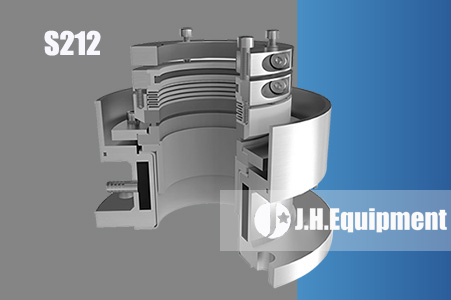

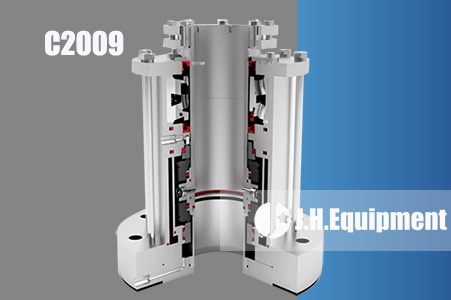

To meet specific sealing demand of agitating system, J.H. provides different mechanical seal solutions to avoid possible leakage in running of glass lined reactors.

Usually we recommend single mechanical seals for glass lined reactors with working pressure inside vessel less than 0.4MPa, which is a reliable and economical solution. While double mechanical seals are recommended for glass lined reactors with working pressure inside vessel exceeding 0.4MPa.

Multiple materials of contact surface between seal rotating ring and stationary ring are optional, such as SiC, ceramic, graphite, PTFE etc.