Product Introduction Product Advantages Working Principle Technical Parameter

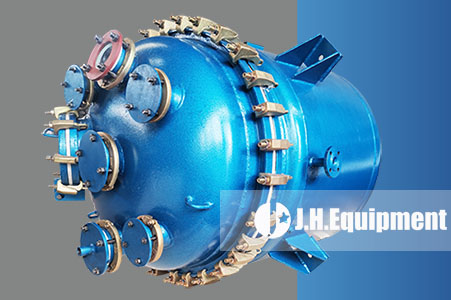

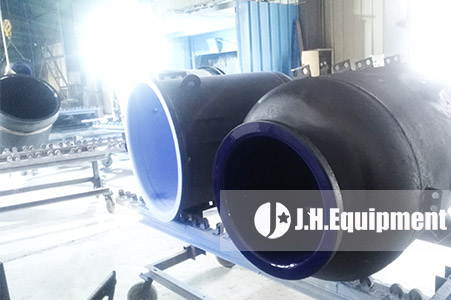

ZK Vertical & Open Type Glass Lined Storage Tanks

| Model | ZK50 | ZK100 | ZK200 | ZK300 | ZK500 | ZK800 | ZK1000 | ZK1500 | ZK2000 | ZK3000 | ZK4000 | ZK5000 |

| Norminal Capacity(L) | 50 | 100 | 200 | 300 | 500 | 800 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Actual Capacity(L) | 61.3 | 121 | 240 | 363 | 590 | 884 | 1112 | 1674 | 2219 | 3336 | 4450 | 5560 |

| Shell I.D. (mm) | 400 | 500 | 600 | 700 | 800 | 1000 | 1000 | 1200 | 1300 | 1450 | 1600 | 1600 |

| Reference Weight(kg) | 150 | 210 | 280 | 380 | 530 | 765 | 860 | 1120 | 1470 | 1970 | 2560 | 2910 |

| Model | ZF3000 | ZF4000 | ZF5000 | ZF6300 | ZF8000 | ZF10000 | ZF12500 | ZF16000 | ZF20000 | ZF30000 |

| Norminal Capacity(L) | 3000 | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | 20000 | 30000 |

| Actual Capacity(L) | 3337 | 4441 | 5550 | 7024 | 8910 | 11142 | 13872 | 17766 | 22217 | 33301 |

| Shell I.D. (mm) | 1450 | 1600 | 1600 | 1750 | 1900 | 2200 | 2400 | 2400 | 2600 | 3000 |

| Reference Weight(kg) | 1700 | 2070 | 2100 | 3000 | 3580 | 4440 | 5660 | 6800 | 8490 | 11880 |

| Model | ZW3000 | ZW5000 | ZW6300 | ZW8000 | ZW10000 | ZW12500 | ZW16000 | ZW20000 | ZW30000 |

| Normical Capacity(L) | 3000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | 20000 | 30000 |

| Actual Capacity(L) | 3337 | 5550 | 7024 | 8910 | 11094 | 13921 | 17756 | 2332 | 33300 |

| Shell I.D. (mm) | 1450 | 1600 | 1750 | 1900 | 2000 | 2000 | 2200 | 2400 | 3000 |

| Reference Weight(kg) | 1732 | 2510 | 3200 | 3730 | 4740 | 5640 | 6700 | 8420 | 12700 |