Product Introduction

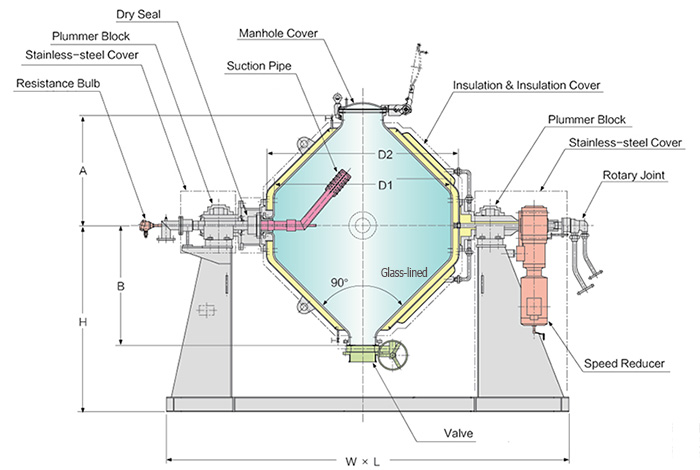

Glass lined double cone rotary dryer (RCVD) designed by J.H. Equipment is suitable for processing corrosive products for drying, mixing or concentrating pharmaceuticals, dyes, pigments, synthetic resins, etc. In many cases, it is possible to appreciably reduce batch time in relation to conventional methods. ( e.g. drying chambers).

In most circumstances, there is GMP requirement for glass lined doube cone rotary dryer and we will cover the GL RCVD first with insulation layer for heat reservation and finally cover it with SS304 polished plate.

For easy operation and safety consideration, we can provide explosive proof control box with HMI monitored by PLC to control the rotating start, stop, speed, heating, vacuum, temperature display etc.

【Production Capacity】: 100~6000L

【Application Industries】: Chemical, pharmaceuticals, dyes, pigment, etc.

【Application Mediums】: Strong corrosive mediums, especially pharmaceutical intermediates that require high purity.